FTTR Thermal Adhesive Coated(TAC) Transparent Invisible Optical Fiber Cable

07/31/2023

GHV 4001 alternative Simplex POF Cable

07/31/2023AFBR-HUS500Z alternative Simplex POF Cable

- RoHS compliant

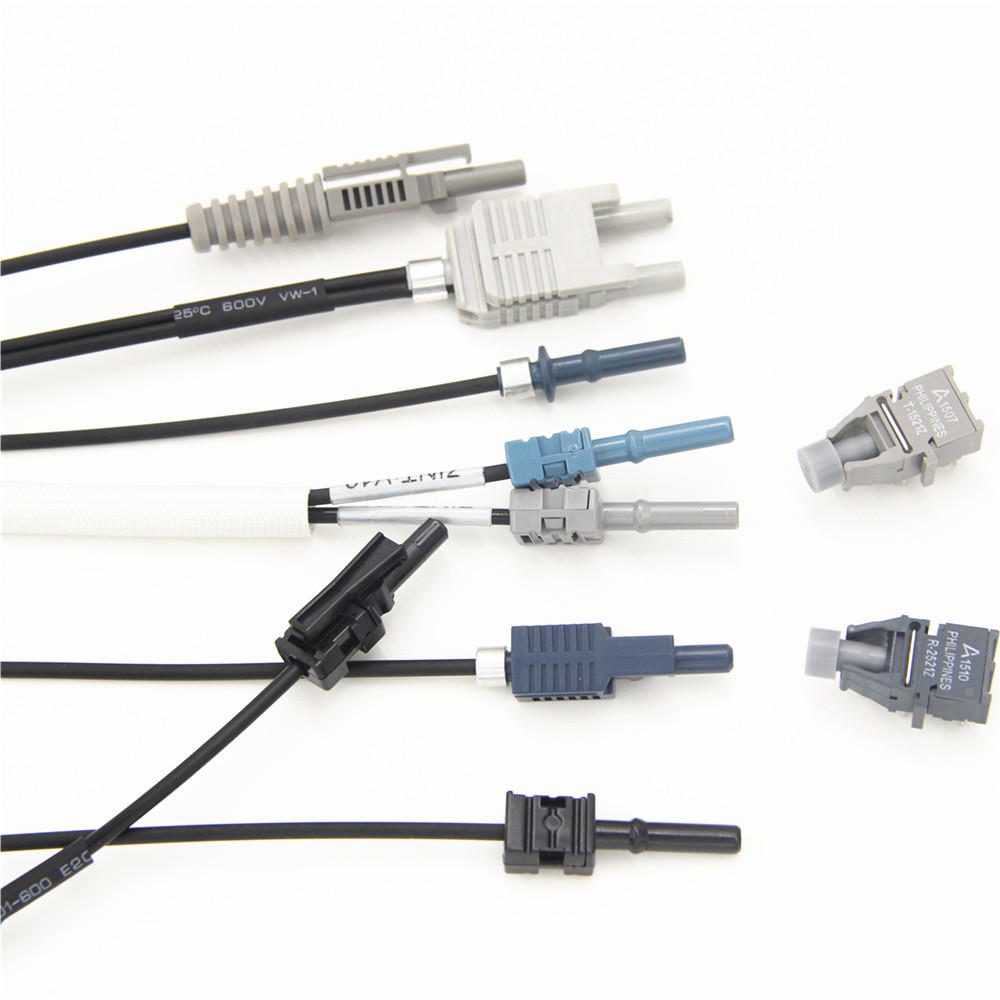

- Compatible with Broadcom Versatile Link family of connectors and fiber optic components

- Extra low loss POF with 0.19 dB/m typical attenuation

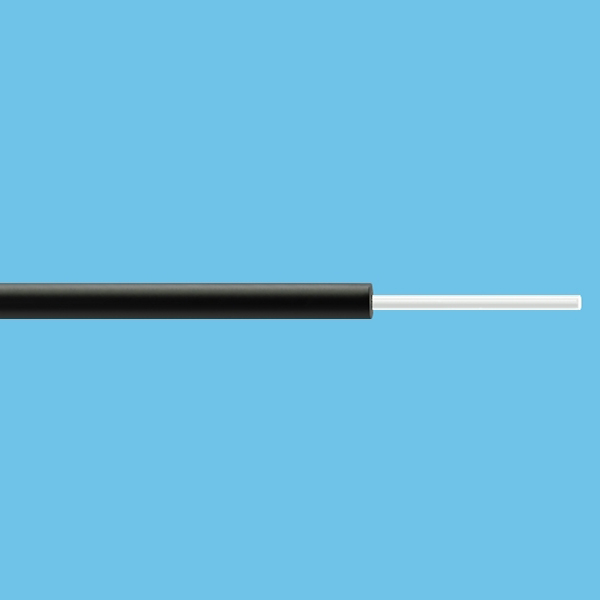

RoHS compliant Halogen-free Simplex POF Cable,black PE/PVC sheath,1.0/2.2mm,0.18dB/M@650nm,1500/2700 meters spool

Our CCVZ2-1000 PMMA Plastic Optical Fiber-POF Cable refers to the PMMA Plastic Optical Fiber jacketed with black flame-retardant PE sheath to protect the PMMA Fiber Core from harsh environment. The CCVZ2-1000 simplex POF cable is an cost-effective alterantive replacement for some well-known brands such as Broadcom Avagao AFBR-HUS500Z, Asahi HMCKU-1000P POF Simplex Cable, HITRONIC J-V2Y(ZN)11Y POF Simplex Cable,Mitsubishi ESKA SH4001 POF Cables for short distance transmission within 100meters.

Simplex POF Cable benefits:

- 55% lower cost than well-known brands

- 50% less power to operate than copper

- 80% reduction of carbon dioxide than copper

- Universally compatible with the Broadcom Avago Versatile Link family of connectors and fiber optic components as transmitters and receivers

- 1mm POF available in 1 grade with 0.19 dB/m typical attenuation (-40°C to +85°C) @650nm

- Waterproof, moisture-proof, EMI free

- ROHS & UL certified

POF Simplex Cable Basic Properties:

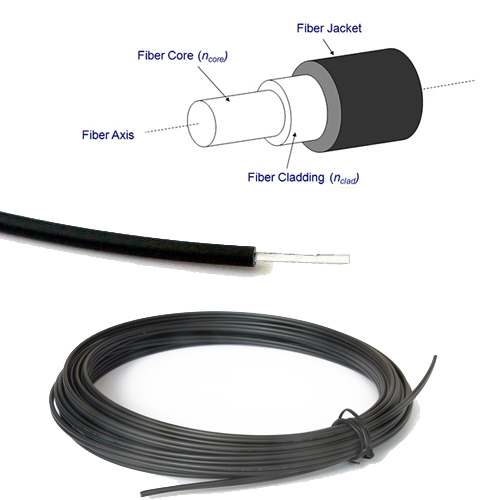

- Fiber Core Material: PMMA

- Cladding Material: Fluorinated Polymer

- Jacketing Material: Black PE or PVC

- Optical Instruction: Step Index Model

- Numerical Aperture:0.5

- Allowable Bend Radius: No less than ten times of optical fiber diameter

- Core Refractive Index:1.492

POF Simplex Cable application:

- Industrial Data Links for Factory Automation and Plant Control

- Intra-system Links; Board-to-board, Rack-to-rack

- Telecommunications Switching Systems

- Computer-to-peripheral Data Links, PC Bus Extension

- Proprietary LANs

- Digitalized Video

- Medical Instruments

- Reduction of Lighting and Voltage transient Susceptibility

- High Voltage Isolation

Technical Parameters:

| Parameters | Unit | Numerical Value |

| Fiber Core Material | — | Polymethylmethacrylate (PMMA) / |

| Cladding Material | Fluroresine Polymer | |

| Jacket Material | — | PE/PVC/PUR |

| Numerical Aperture | — | 0.5 |

| Working Wavelength | nm | 525~650 |

| Incident Angle | — | ≤60° |

| Bandwidth | MHz·100m | ≥10 |

| Bending Radius | — | ≥10 times of fiber diameter (Temporary) |

| ≥20 times of fiber diameter (Permanent) | ||

| Operating Temperature | ℃ | -55~ +85 (CC2 series) |

| -40 ~ +70 (CC series) | ||

| Storage Temperature | ℃ | -40 ~ +70 |

| Refractive Index | — | Step index |

| Performance | Criteria for Acceptance and/or [ Test Conditions ] | Unit | Value | |

| Maximum Rating | Storage Temperature | No Physical Deterioration [ in a Dry Atmosphere ] | ℃ | – 40 ~ 85 |

| Operating Temperature | No Deterioration in Optical Properties [ in a Dry Atmosphere ] | ℃ | – 40 ~ 70 | |

| No Deterioration in Optical Properties [ under 95% RH condition ] | ℃ | N/A | ||

| Optical Properties | Transmission Loss | (650 nm Collimated Light) [ 25°C 50% RH ] | dB/m | 0.20 Max. |

| Transmission Loss under 95% RH | (650 nm Collimated Light) [ Operating Temperature ] | dB/m | 0.19 Max. | |

| Mechanical Characteristics | Minimum Bend Radius | Loss Increment <0.5 dB [ A Quarter Bend ] | mm | 30 |

Ordering Information:

| Part Number | Fiber Diameter | Cable Diameter | Spool Length | Attenuation |

| (mm) | (mm) | (M) | (dB/M@650nm) | |

| CC2-1000U | 1.0±0.06 | 2.2±0. 07 | 1500/2600/5200 | ≤0.15 |

| CC2-500 | 0.50±0.03 | 1.0±0.05 | 1000/6000 | ≤0.20 |

| CC2-750 | 0.75±0.05 | 2.2±0.07 | 2700 | ≤0.18 |

| CC2-1000 | 1.00±0.06 | 2.2±0. 07 | 1500/2600/5200 | ≤0.18 |

| CC2-1500 | 1.5±0.09 | 2.5±0.10 | 700 | ≤0.18 |

| Part Number | Fiber Diameter | Cable Diameter | Spool Length | Attenuation |

| (mm) | (mm) | (M) | (dB/M@650nm) | |

| CC-500 | 0.50±0.03 | 1.0±0.05 | 1000/6000 | ≤0.30 |

| CC-750 | 0.75±0.05 | 2.2±0.07 | 2700 | ≤0.25 |

| CC-1000 | 1.00±0.06 | 2.2±0. 07 | 1500/2600/5200 | ≤0.25 |

| CC-1500 | 1.5±0.09 | 2.5±0.10 | 700 | ≤0.25 |